Using Limestone for Stall Bedding: What You Need to Know About Barn Lime

Table of Contents

View Lime Stall Bedding Find Your Local Distributor

Author/Reviewed By: Josh Miller, Sales Manager: Baker Lime & North America Minerals

Published: 3/16/2018 – Updated: 6/26/2020

Raising livestock is a serious business. Whether it’s dairy cattle or show horses, the care and attention given to livestock animals’ overall health and well-being are vital. It’s not only critical to protect a livestock investment for financial reasons. It’s also the morally and ethically right thing to do. Barn lime can help.

Many cows and horses spend a good deal of their day in a stall. Barn-kept livestock is out of the elements and protected from extreme temperatures, pesky insects and dangerous predators. Also, many livestock farms simply don’t have the room to pasture their animals, which is especially true in dairy operations.

Stalls are highly efficient for individualizing animals. Stall quarters give horses and cows some personal space while allowing a sense of natural herding. Most livestock heads are perfectly content to stay in their stalls, provided they’re comfortable. When animals aren’t comfortable in their stalls, they can easily develop sores and diseases. Comfort level greatly depends on stall floor construction and covering. Today, many keepers use limestone for cattle and livestock stall bedding.

Types of Stall Floors

Just as there are various barn designs, there is a wide range of stall floors. Designing and building a stall floor depends on many factors, including the different animal species being housed. Stall bedding options for horses and those for cows have different requirements. Milking cows and those giving birth need continuously clean environments. Stallions, on the other hand, tolerate more soiled conditions.

Livestock owners vary in their opinions of what makes the perfect stall floor, but they all agree that a proper floor makes a huge difference in their animal’s well-being.

Characteristics of a good stall floor include:

- Ease on livestock legs and overall skeletal system

- Ability to stay dry or at least control moisture well

- Non-odor retentive quality and minimized waste smell

- Excellent traction for animals to lay down and get up

- Durability and damage-resistance from livestock hooves

- Low maintenance and easy cleaning

- Affordability and cost-effectiveness

Because livestock owners are also business owners, product value is a critical consideration when choosing stall floor material. For an average 12-foot by 12-foot area, material costs can range from less than $50 to $400 per stall. Each owner will have their own methods of determining value, but looking at the above characteristics is a great way to narrow down the options.

Without a doubt, crushed limestone has each of the above qualities. It can be the ideal stall floor material, depending on the type of floor surface desired. There are two main stall floor types, and each one has its purpose and construction techniques. Barn designers start by specifying one of these two types of stall surfaces:

- Porous stall beds: Containing loose material, porous stall beds drain naturally. Typical stall floors in the old days were nothing more than natural earth, similar to what appeared in the nearby pasture. That evolved over time with imported gravels and free-draining minerals like crushed limestone.

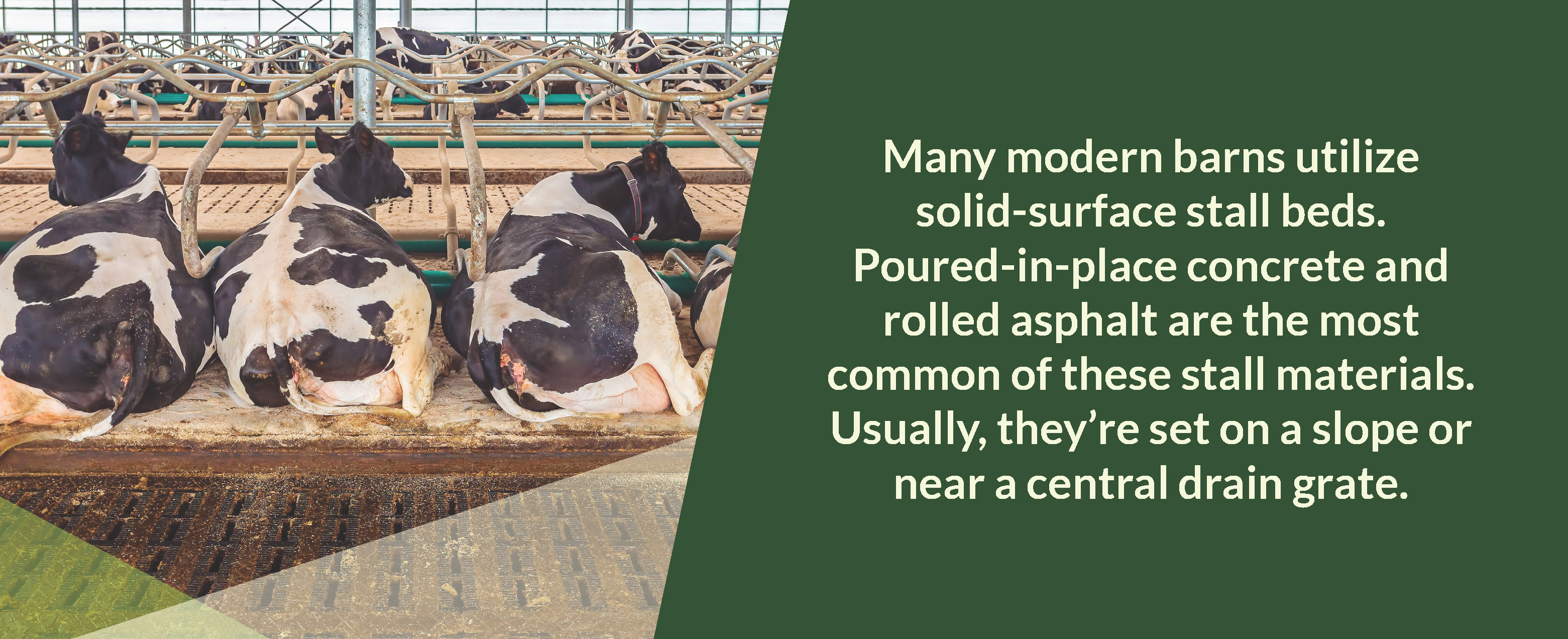

- Impervious stall beds: Many modern barns utilize solid-surface stall beds. They’re impervious to drainage and require artificial runoff to control animal waste and wash water. Poured-in-place concrete and rolled asphalt are the most common of these stall materials. Usually, they’re set on a slope or near a central drain grate.

Each of these two stall bed surfaces has pros and cons. Porous surfaces tend to be softer and easier on large animals. However, these floors require a lot of maintenance and continual material replacement. Impervious surfaces are harder on cows’ and horses’ legs and muscles, but impervious stall beds are durable and provide long-term cost-effectiveness.

Crushed limestone offers the perfect compromise between porous and impervious stall floors. Limestone is a natural, inert material that’s easily placed and compacted. It gives the strength and durability of concrete or asphalt at far less cost. Even if well-packed, limestone allows porosity for liquids to evenly drain. However, limestone for livestock stalls, such as using lime in horse stalls, still needs additional bedding for optimum animal health.

Learn More About Our Stall Bedding Limestone

Bedding Choices for Livestock Stalls

Livestock stall floors have three construction components. First is the subsurface or base support. Today, all barn designs have topsoil removed, regardless of whether they have porous or impervious beds. Left in place, organic topsoil turns into a mess and presents high health hazards from decomposition, which allows weed growth and insect breeding. Barn builders remove all natural organic material and then build up an inert base.

Next, builders lay a top surface. It might be cast concrete or pavement for impervious stall floors, or it might be some porous material like sand, gravel or crushed limestone. Other materials are available as well, such as wood planks, rubber pavers and polypropylene mats. However, due to budget and maintenance issues, these alternatives are not commonly used.

This completes the main floor base, but whether the floor base is solid or free-draining, all stalls still require some form of bedding material. Softer top dressings serve several purposes. One is adding a spongy layer that the animal can comfortably stand on or lie down in. Another reason for using top bedding is waste management. Liquid urine and solid feces or manure need strict control.

Good stall bedding has five characteristics: It must provide comfort, control moisture, stay clean, be inert and have the proper particle size. Crushed limestone does an excellent job of delivering a semi-solid base that drains urine and allows easy manure muck-out. However, limestone for livestock stalls still needs some sort of surface bedding. The following are the options or choices to use as livestock bedding material:

- Straw: Most livestock raisers use straw as their universal choice — a by-product of small grains like wheat and barley. It’s the non-palatable stocks and sheaths left over after grain harvest. Straw is soft, absorbs liquids well and doesn’t adhere to animal coats. It’s also cheap and readily available.

- Hay: Hay is a second choice next to organic straw. It’s a whole organic material that is palatable and usually used for animal feed. Only poor-grade hay gets placed as stall bedding. It’s also soft, controls moisture and manages well on the floor. On the downside, hay contains seeds, which germinate and cause pest and weed issues.

- Wood Shavings: Shavings are some of the best stall bedding materials. Sawmills produce shavings in the kiln-dried lumber planning process. Shavings are mid-sized and manage well on stall floors. They’re exceptionally clean and soft, making them ideal coverings over crushed limestone surfaces. Unfortunately, shavings are in high demand and can be costly.

- Wood Chips: Wood chips also work well to provide cushioning and liquid management. Chips are made during debarking of raw logs. They contain original moisture and haven’t been artificially dried as with shavings. Chips introduce an already wet environment that encourages fast rot and mold. Chips also have natural oils in the bark that can stain an animal’s coat.

- Sawdust: Although sawdust is cheap and plentiful, it’s a poor choice for livestock bedding material. Sawdust particles are too fine. When wet, this material forms clumps and retains liquid rather than draining freely. Sawdust also sticks to livestock coats and makes grooming a chore. With dairy and nursing cows, sawdust stays on udders, which is terribly unhealthy.

- Sand: As with sawdust, sand is too fine for practical use. Although it’s inexpensive and in unlimited supply, sand is hard to maintain. It tracks when wet and blows when dry. Sand does have one clear advantage, though — it’s soft and forgiving to hooves and hides.

- Clay: This material is a popular one for bottom base layers. Clay occurs naturally in most parts of the country and is virtually free. Left undisturbed, clay bases are exceptionally stable. However, loosed and wetted clay turns into a soupy mess that sticks to animal hooves like soggy socks. Pure clay also has no percolation and traps water. Barn builders occasionally blend clay with sand to give bigger particle size and a better drainage compromise.

- Limestone dust: Crushed limestone in a size 10 Mesh screening is the optimum livestock stall base material. That specific crush and screening is the perfect size to let particles pack but stay porous enough to drain.

- Other materials: Barn keepers can get highly creative in sourcing stall bed supplies. Availability and affordability are key factors in sourcing bedding material. Hemp is an interesting material as a straw substitute. It’ll be more available as the American hemp industry expands. Many owners use newspaper and other recycled paper products as bedding. Some even add corn stubble, peanut hulls and tobacco stems.

What Is Barn Lime?

Limestone is one of the world’s oldest building materials. It’s abundantly available on many continents, including North America. Limestone is a sedimentary rock created from organic sea materials that compressed and petrified over hundreds of millions of years.

Limestone deposits now occur inland at high elevations that once were old ocean beds. Places like York County, Pennsylvania are famous for top quality, high-producing limestone quarries. This region supplies the central part of the eastern United States with a continual supply of solid and crushed limestone.

Most limestone quarried by companies such as Baker Lime in York County supply the agriculture and livestock industry. Baker Lime’s primary product is high-grade dolomitic limestone rather than low-purity hydrating lime. There’s a distinct difference between dolomite limestone, or ag-lime, and hydrating lime. Dolomite lime is also called barn lime and gardening lime. Hydrating limestone is caustic, and it’s more suitable for building blocks and landscaping features.

Dolomite limestone is naturally alkaline. That means it’s low on the pH scale and polar to high-acidic materials like most composting organic compounds, including animal manure. Ag-lime usually comes as a powder that’s added to soil content. That lowers or neutralizes pH levels for optimum plant growth.

Dolomite lime also contains highly important trace elements, including calcium, magnesium and manganese. When dolomite lime is mixed with other main fertilizers like nitrogen, phosphorous and potassium, they provide perfect plant-growing conditions.

Crushed Limestone Is Ideal for Livestock Stalls

Powdered dolomite lime is excellent for all types of plant agriculture, and solid hydrating limestone is great for building. Both serve their purposes and have tremendous demand. However, there’s a medium between powdered limestone and massive chunks. It’s called crushed limestone, and it comes in various screening sizes. 10 Mesh limestone crush is the one used in livestock stalls.

Video – Benefits of Lime Stall Bedding

So why is crushed limestone ideal for livestock stalls? Because it meets and exceeds all the right requirements for a livestock stall base. Lime crush has every feature a barn owner could want in their stall floor. Barn lime uses and the benefits of using lime for stall bedding base include that it:

- Provides stability and durability while being available and affordable

- Lowers ground pH levels and discourages weed growth

- Makes the subsurface alkaline and controls insect and pest invasion

- Neutralizes acidic manure and litter

- Reduces unpleasant odors from animal waste

- Wicks water from wet areas in stalls and aisles

- Provides excellent traction for livestock movement

- Mixes well with top dressings like wood chips and straw

- Dilutes livestock urine and controls ammonia

Ammonia control is a highly important issue in livestock stalls. Animal urine contains a chemical called urea. On its own, urea is colorless, odorless and non-toxic. But if urea is left to pool as urine, it quickly changes chemical composition and off-gasses dangerous ammonia fumes. Exposing livestock to ammonia brings on all sorts of health issues, including respiratory diseases, skin disorders and poisoned milk production.

Limestone stall bases naturally react with urine and control urea from becoming ammonia gas. Crushed dolomite lime continually interacts with urea. There’s no diminishing effect, no matter how long the limestone has been in place. 10 Mesh crushed limestone has an indefinite life. It also gives the benefit of transferring microscopic trace elements into manure spread as field fertilizer.

Most farms are holistic, which means they’re a combination of livestock producers and ag plant horticulturists. A pre-limed organic fertilizer, like manure mucked out of crushed limestone-based stalls, is ideal for correcting field soil pH levels. It’s a win-win for all farmers.

The key to using limestone on stall floors is its screening size. Large particle screen sizes like 20 Mesh are too large to interlock and compact. Screenings under 10 Mesh become powdery and won’t compact or interlock. However, the proper limestone size makes a perfect base to support large animals while still offering clean comfort.

Get A Quote for Lime Stall Bedding

Where Can I Buy Barn Lime Near Me?

Since 1889, our Baker Lime quarry in York County, Pennsylvania produced the best ag-grade dolomite lime in the eastern United States. This exceptional limestone is in such demand that we mine and ship material 24 hours a day, seven days a week, all year long. While farmers depend on Baker powdered dolomite products for field treatment, more and more livestock owners turn to Baker for 10 Mesh stall bases.

Since 1889, our Baker Lime quarry in York County, Pennsylvania produced the best ag-grade dolomite lime in the eastern United States. This exceptional limestone is in such demand that we mine and ship material 24 hours a day, seven days a week, all year long. While farmers depend on Baker powdered dolomite products for field treatment, more and more livestock owners turn to Baker for 10 Mesh stall bases.

Baker 10 Mesh Free Stall Bedding is pure crushed limestone. It’s non-toxic and 100 percent safe for livestock like horses and cows. Some farms raising pigs, goats and sheep also turn to Baker Lime for their stall floors. All livestock owners report their limestone-floored stalls being easily cleaned and long-lasting. Free drainage is also a prime benefit in managing livestock stalls.

Trust Baker Lime to supply you with the best 10 Mesh crushed limestone available in eastern America. We regularly supply all of Pennsylvania as well as our neighboring states of Delaware, New York, New Jersey, Maryland and both Virginias. Baker Lime also provides for other areas by partnering with customers to create long-term, mutually beneficial relationships.

For more information on our 10 Mesh Limestone Free Stall Bedding or other fine dolomite lime products, call Baker Lime at 800-233-1991. You can also learn more about purchasing our product and request a quote from Baker Lime today.